CNC Machining Versatility

You often get a wide range of product possibilities into the use since CNC machines are highly practical. From small parts to large, they take pride in manufacturing with the finest quality all time. This ensures that small and large products can be created to the same specification from CNC machines. The CNC machine use is very versatile, since it can work with a large amount of materials (aluminium, steel, plastics and ceramics just to name some) hence suitable for many projects as well.

The Simplification of Industrial Production

The speed and convenience of making things in factories using CNC machines were endless. They are more time-saving and produce high-quality products. Before, workers did almost everything by hand and this is where a lot of mistakes come from so the result would be not as good due to its unevenness. Thankfully, the evolution of CNC machines makes manufacturing less labor intensive. That way, they can produce parts with fewer people and less room for error - making sure each part is manufactured exactly right every time. This automation has allowed several businesses to scale and run more efficiently.

CNC Machining for Cost-Effective Custom Manufacturing

CNC devices are also a great way to manufacture unique components for customers without requiring investing large volumes of bucks. Custom manufacturing means making parts to order, which is often more expensive than mass production and especially when the part can be one of a kind. But well, that is exactly where the bonus falls in: using traditional manufacturing methods makes these custom parts expensive to create if they do not have a specific tool for each unique part; but with CNC machines it becomes cheaper. Since CNC machines works with almost any material, creating multiple shapes and sizes parts does not mean you are paying for more than needs to respondent.

Now lets take a closer look to CNC technology.

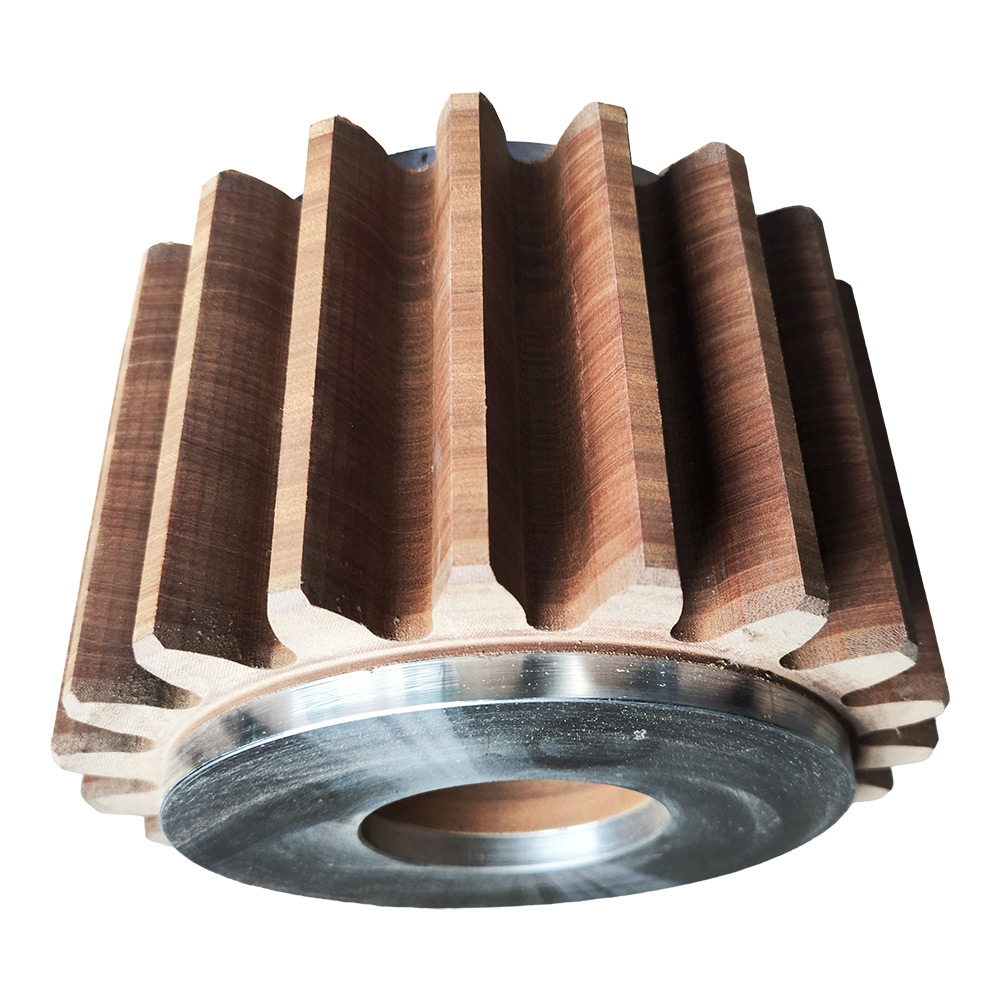

Cutting tools are used in CNC machines to accomplish tasks such as drilling, turning and milling. The tool rotates to do its work. The workpiece is processed by the spindle on a CNC machine with its ability to spin and move in different direction until it forms into any shape. The machine has sensors cnc parts inside that monitor all the time for where is the spindle, and keeps an eye on whether everything is running accurately. This technology helps the Organifi make sure that any final product meets the necessary specifications.

The control software inside the CNC machine is equally important, its job is to determine how the machine moves and that everything gets made right. With this program, workers could generate comprehensive programs and if necessary adjust their progress from a remote location - which is great for busy factory floors.

The Bottom Line

Ultimately, CNC machining has changed the way factories produce items because of its ability to make parts rapidly and afford-ably. With the cutting edge technology of CNC machining, this is cnc machining part achievable as manufactures are able to produce complex parts that have an intracacy part then they ever had before. CNC machines can work with a variety of materials which makes them useful in all of these industries. In addition, CNC machines make the process much more streamlined and greatly reduce errors that are found frequently in products. With CNC machines, custom manufacturing has become cheaper as well because they remove the need for special tools. All in all, CNC machining is an incredibly valuable technology that has revolutionized industrial manufacturing and Products continues to create new opportunities for innovation across the industry.